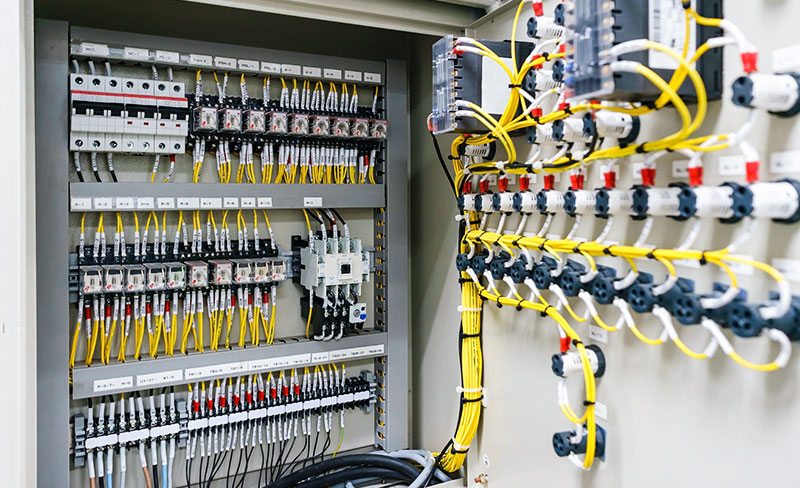

Our team consists of highly skilled professionals with extensive experience in instrumentation and electrical fabrication. We specialize in designing, fabricating, and assembling a wide range of components, including UL-508A control panels, electrical racks, solar skids, E-Houses, Primary Distribution Centers, and various racks. Additionally, we manufacture skidded process equipment, such as Chemical Injection Packages, Hydraulic Power Units, and LACT units. Our in-depth knowledge of industry standards and regulations ensures that all fabricated products meet or exceed quality and safety requirements.

Understanding that every project has its specific needs, we offer tailored fabrication solutions. Our engineers collaborate closely with clients to develop designs that meet their unique operational requirements. This client-centric approach allows us to deliver customized I&E solutions that enhance performance and reliability.

Lynn Energy Services is equipped with state-of-the-art fabrication facilities that enable us to efficiently manufacture high-quality electrical components. Our facilities are outfitted with advanced tools and technologies, ensuring precision in every aspect of the fabrication process. From assembly to wiring, we maintain strict quality control to deliver superior products.

Quality is a cornerstone of our I&E fabrication services. We implement rigorous quality assurance processes throughout the fabrication lifecycle. Each component undergoes thorough inspections and testing to ensure compliance with industry standards and specifications. Our commitment to quality guarantees that our products are reliable, safe, and ready for seamless integration into client systems.

Safety is paramount in all our fabrication activities. We adhere to stringent safety protocols and industry regulations to create a safe working environment for our team and partners. Our I&E fabrication processes prioritize risk management and safety measures, ensuring that every project is executed without incident.

We understand the importance of timely project delivery. Our streamlined fabrication processes, coupled with effective project management, allow us to meet deadlines without compromising on quality. We work diligently to ensure that our I&E components are delivered on schedule, supporting the overall success of our clients’ projects.

At Lynn Energy Services, we believe in the power of collaboration. We maintain open lines of communication with our clients throughout the fabrication process, providing updates and addressing any concerns. This collaborative approach fosters h4 partnerships and ensures that our clients are satisfied with the end results.

With our comprehensive Instrumentation and Electrical fabrication services, Lynn Energy Services is dedicated to delivering high-quality, reliable solutions that enhance operational efficiency and safety in the energy sector. Our commitment to excellence ensures that we meet the evolving needs of our clients while supporting their goals for success.